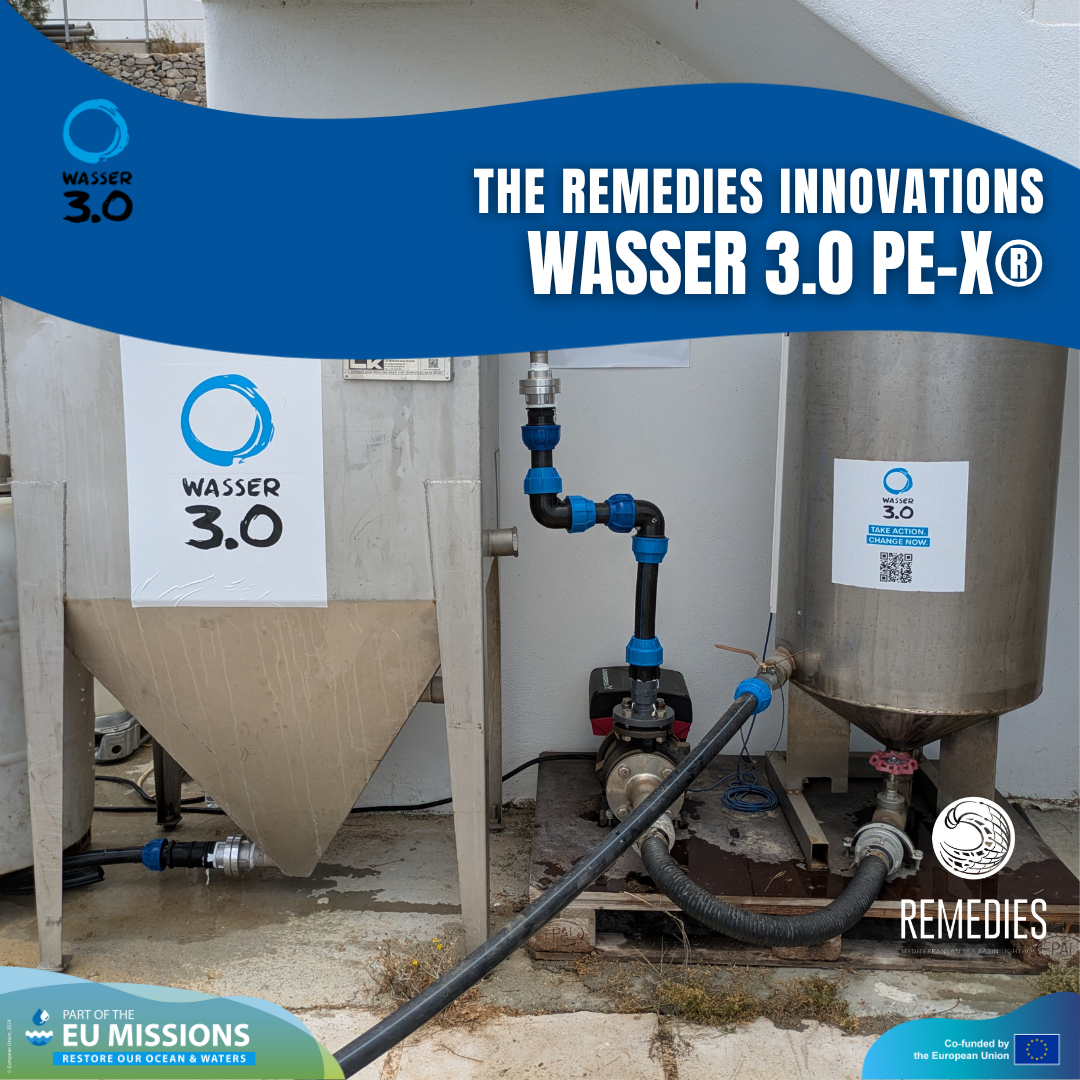

An innovative solution addressing microplastic pollution in wastewater through an advanced two-stage process of detection and removal.

Related REMEDIES Pillars: Detection and Monitoring, Collection and Valorisation, and Prevention and Zero-Waste Solutions.

Partner(s)/Owner(s): Wasser 3.0 gGmbH

Made for: Industrial users, Wastewater treatment plants (WWTPs), Plant builders, Environmental protection bodies, and analytic laboratories.

What is Wasser 3.0 PE-X®?

Wasser 3.0 PE-X® is an innovative solution addressing microplastic pollution in wastewater through an advanced two-stage process of detection and removal. Novel fluorescent dyes are used for monitoring and process control, and the proprietary Clump & Skim Technology, using abcr eco Wasser 3.0 PE-X® (for wastewater, freshwater, salt water), works with any type of polymer, with the process removing up to 95% of the microplastic load.

Wasser 3.0 PE-X® has been used as a tertiary or advanced treatment step at WWTPs and (which is more important) in industrial processes (up to now, application in >15 segments from production, manufacturing, recycling) for a sustainability upgrade beyond CO2. In addition, 100% of the removed waste can be reused, which increases the contribution to resource conservation and at the same time creates a new secondary source of income across the value chain.

Wasser 3.0 PE-X® requires 20% lower CapEx than mainstream alternatives (e.g. filtration-based methods, electrocoagulation, hydrocyclones) and up to 75% less operational costs. Additional savings are realized through reductions in energy, chemical and water consumption; waste-as-resource approach & circular economy (for water, chemicals, removal products), maintenance, and operational costs.

Developed by Wasser 3.0 gGmbH, the technology is advancing from Technology Readiness Level (TRL) 5 to TRL 8 by the end of the REMEDIES program, ensuring its readiness for large-scale implementation in real-world applications.

Impact: What Challenges Does This Technology Address?

Microplastic pollution in water systems presents significant environmental and health risks. Wasser 3.0 PE-X® aims to address key challenges such as:

- Detection and Quantification: The integration of fluorescent dyes enables precise identification and quantification of microplastics in wastewater streams, providing reliable and comparable data for stakeholders.

- Efficient Removal: By leveraging physical agglomeration and water-induced chemical fixation, the system captures microplastics effectively, preventing them from entering natural water bodies.

- Resource Recovery: The collected microplastics can be repurposed for secondary applications, promoting circular economy practices.

This solution, tested at the Mykonos Demo Site within REMEDIES and at an industrial replication site, aligns with all the three pillars of the REMEDIES program — Detection and Monitoring, Collection and Valorisation, and Prevention and Zero-Waste Solutions.

Unique Value Proposition: What Makes This Technology Stand Out?

Wasser 3.0 PE-X® offers a groundbreaking solution with several unique advantages:

- Superior Efficiency: The Clump & Skim Technology achieves up to 95% removal of microplastics by promoting rapid particle agglomeration and stable separation.

- Cost-Effectiveness: The system requires 20% lower capital expenditure (CapEx) and up to 75% lower operational expenditure (OpEx) compared to traditional membrane filtration or hydrocyclone systems.

- Scalability and Flexibility: The modular design allows adaptation to various industries, handling flow rates ranging from 1 to 5 m³/hour.

- Sustainability Focus: The technology reduces energy consumption, operational costs, and carbon emissions, while enabling reuse of captured microplastics in construction materials.

- Technical Specifications:

- Modular containerized systems available in 250 L and 1000 L capacities.

- Automated operation with IoT sensors for real-time monitoring of pH, ORP, and conductivity.

- Adaptable for diverse industrial applications, including recycling, manufacturing, and wastewater treatment.

User: Who Can Benefit from This Technology?

A wide range of stakeholders can leverage Wasser 3.0 PE-X® to enhance their environmental management practices. Analytical laboratories and technology providers can integrate the system for precise microplastic monitoring and remediation. Wastewater treatment plants benefit from improved efficiency and compliance with environmental regulations. Environmental protection bodies and NGOs can utilize the technology to support marine conservation initiatives, while industrial users across sectors such as manufacturing and recycling can adopt it to minimize their environmental footprint and achieve sustainability goals.

Exploitation Pathway: How Will This Technology Be Put Into Action?

The deployment strategy for Wasser 3.0 PE-X® involves multiple pathways to maximize impact and accessibility:

- Commercial Deployment: Offering rental, service, and consulting packages to industries and municipal facilities.

- Research Collaborations: Partnering with academic institutions and environmental agencies for further development and validation.

- Public Awareness Campaigns: Engaging stakeholders through workshops and training sessions to promote the adoption of sustainable water treatment practices.

- Regulatory Integration: Working with policymakers to establish standards for microplastic detection and removal in wastewater treatment processes.

Through these pathways, Wasser 3.0 PE-X® aims to drive significant progress in combating microplastic pollution and fostering a sustainable water management ecosystem.

Discover More

Learn more about Wasser 3.0 gGmbH, a leading REMEDIES program partner, here.

- Explore the Marketplace Page for the Wasser 3.0 PE-X®, here!

- Watch the Technology Presentation of YouTube, here.

- Access additional publications and research on the technology:

DETECTION:

Sturm, M.T.; Argyropoulou, D.; Myers, E.; Korzin, A.; Ronsse, P.; Zernikel, O.; Schober, D.; Schuhen, K. Comparative Long-Term Monitoring of Microplastics in the Effluent of Three Different Wastewater Treatment Plants with Two, Three, and Four Treatment Stages. Water 2025, 17, 711. https://doi.org/10.3390/w17050711

Sturm, M.T.; Myers, E.; Korzin, A.; Schober, D.; Schuhen, K. Long-Term Monitoring of Microplastics in a German Municipal Wastewater Treatment Plant. Microplastics 2024, 3, 492-502. https://doi.org/10.3390/microplastics3030031

REMOVAL:

Sturm, M.T.; Myers, E.; Schober, D.; Korzin, A.; Schuhen, K. Beyond Microplastics: Implementation of a Two-Stage Removal Process for Microplastics and Chemical Oxygen Demand in Industrial Wastewater Streams. Water 2024, 16, 268. https://doi.org/10.3390/w16020268.

Puhar, J.; Sturm, M.T.; Myers, E.; Schober, D.; Korzin, A.; Vujanović, A.; Schuhen, K. When Technology Meets Sustainability: Microplastic Removal from Industrial Wastewater, Including Impact Analysis and Life Cycle Assessment. Water 2025, 17, 671. https://doi.org/10.3390/w17050671

Sturm, M.T.; Myers, E.; Schober, D.; Thege, C.; Korzin, A.; Schuhen, K. Adaptable Process Design as a Key for Sustainability Upgrades in Wastewater Treatment: Comparative Study on the Removal of Micropollutants by Advanced Oxidation and Granular Activated Carbon Processing at a German Municipal Wastewater Treatment Plant. Sustainability 2022, 14, 11605. https://www.mdpi.com/2071-1050/14/18/11605